Nix Engineering Group offers a range of market leading products via our in-house Abrasive Blasting and Coatings application facility.

The Nix facility is unique in nature as it is fully contained within a closed environment and offers clients the ability to receive blasting and coating year-round without the common delays that inclement weather conditions can cause. The fully enclosed blasting room offers up to two blasting operations that can run simultaneously within the blast room. The room has a fully ducted and environmentally friendly dust extraction system that maintains air quality and particulate drop out as well as housing the latest in garnet recovery and recycling systems. The room is LED light flooded ensuring that we get the best quality finished products on time, everytime.

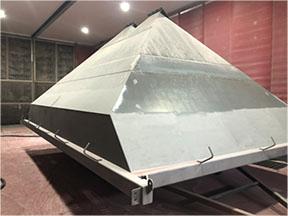

The fully retractable and versatile coatings application booth allows Nix to apply surface coatings with ease due to the ability to adapt to all shapes and sizes by simply adjusting the booth length to suit our needs. The booth runs full internal LED lighting and complete particle separation via means of an extraction filter wall system. Coatings are applied utilising industry standard methods being complete air-over or air-less methods as well as the latest in two-part HBE mix-at-gun systems for the ultimate in corrosion protection.

Nix Engineering Group offer abrasive blasting to the Agriculture, Mining and Water Infrastructure sectors as well as general day to day minor industries. Our coating application and quality standards meet all the major stakeholder needs and are backed by fully trained and certified team of staff who understand and manage our delivery within the company wide ISO 9000-2015 accreditation. We utilise the most common and industry standard coating systems from Wattyl, Henkel, PPG, Jotun, International, Canusa and Akzo Nobel.